Business Processes

Business Processes

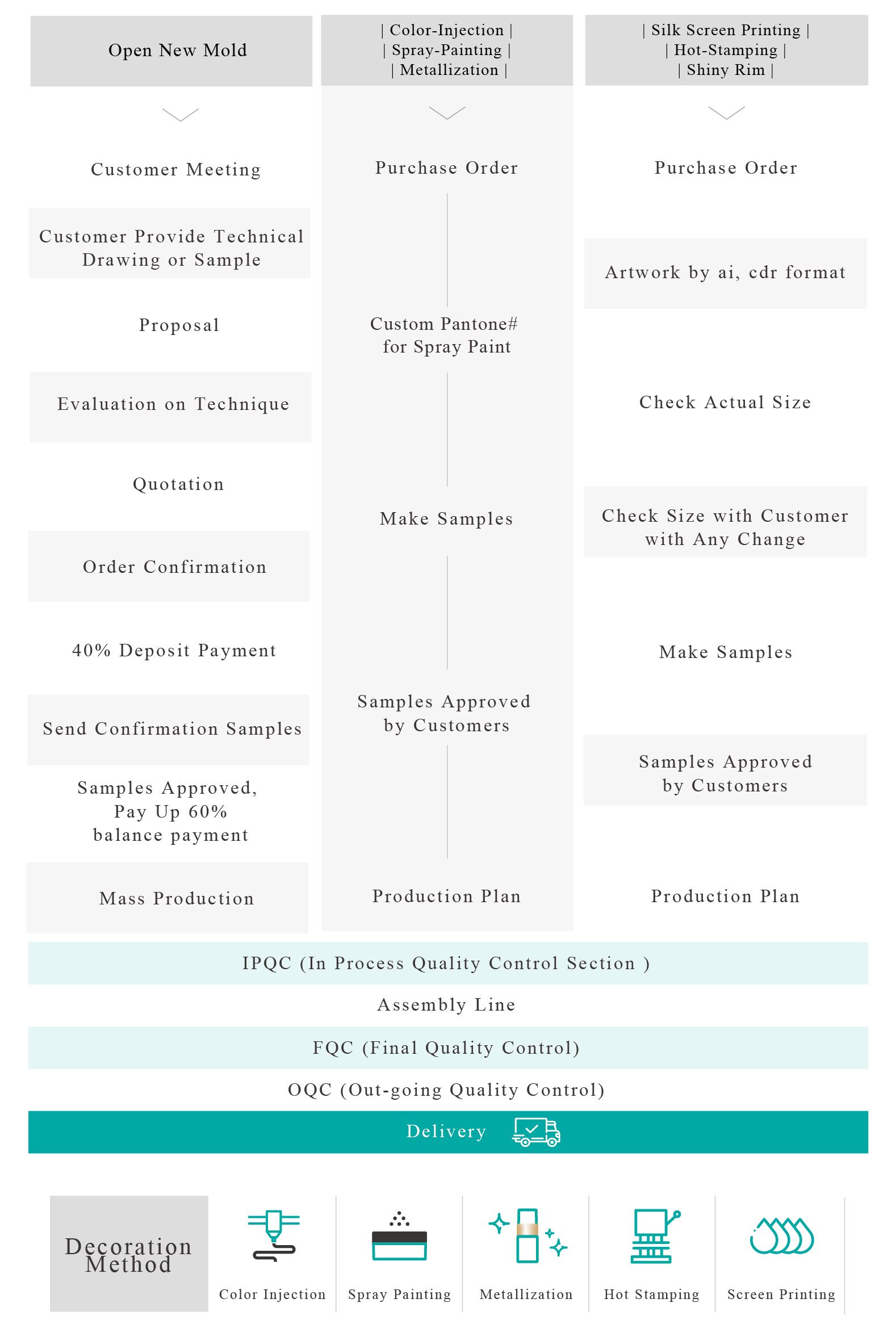

Cosmetic plastic containers and plastic products undergo various stages of product design, mold development, customer private mold development, and product production to quality inspection during the research and development phase. These details are crucial in ensuring product quality and customer satisfaction. The following will provide a detailed introduction to these professional aspects.

Product Design:

When designing cosmetic plastic containers or plastic products, considerations such as functionality, aesthetics, safety, and sustainability are essential. Businesses or research and development teams collaborate with customers to identify product needs and goals, and then carry out design work based on these requirements. This includes presenting creative concepts, designing the product's appearance and structure, and selecting materials.

Mold Development:

Molds are crucial tools for producing plastic products. Once the product design is completed, dedicated molds need to be developed for manufacturing the products. Mold development involves the following steps:

Designing the mold structure: Engineers design the mold structure, including the cavity, cooling system, and demolding mechanism, based on the product design.

Mold manufacturing: Mold manufacturing requires high-precision machining techniques. Common manufacturing methods include milling, electrical discharge machining, and wire cutting.

Testing and adjustment: After the mold is completed, trial molds are carried out to ensure the accuracy of the mold and the quality of the product. If adjustments are necessary, the mold is modified and optimized accordingly.

Customer Private Mold Development:

For some customers, they may have specific design requirements or prefer molds exclusive to their own brands. This development process involves more in-depth communication and discussions on design details to ensure that the final mold meets the customer's requirements.

Product Production:

Once mold development is completed, product production can commence. This involves using injection molding or other molding methods to manufacture products using plastic materials. The main steps of product production include:

Material preparation: Selecting suitable plastic materials based on the product design and requirements. These materials are typically provided in the form of pellets or powder and require precise measurement and mixing.

Injection molding: Heating the selected plastic material and injecting it into the mold to fill the cavities. It is then cooled and solidified to obtain the desired shape and structure of the product.

Separation and processing: Once the product is removed from the mold, separation and subsequent processing may be necessary. Examples include removing mold markings, trimming edges, performing surface treatments, or assembling other components.

Quality Inspection: Conducting quality inspections during the production process is crucial. This includes visual inspections, dimension measurements, and physical performance testing, among others, to ensure that the product meets design requirements and customer expectations.

Packaging and Shipping: After passing the quality inspection, the products are packaged to ensure safe transportation and storage. Products are labeled, barcoded, or undergo other identification processes according to customer requirements, and then shipped to the customer's location or distribution center.

For cosmetic plastic containers and plastic products, these professional details ensure high quality and customer satisfaction from the research and development phase to production. Manufacturers and design teams work closely together to ensure that the product's functionality, appearance, and safety meet customer needs. Meanwhile, strict quality control and inspection processes ensure that products meet consistent quality standards. The professional execution of these details enables cosmetic plastic containers and plastic products to succeed in the market.